A milestone day: The first controlled rotations for the HAPP test apparatus! (clap, clap, clap)

At this point all the fundamental building blocks have come together. We have some 3D-printed jet nozzles attached to a pneumatic valve system that's controlled by an on-bard IMU. We developed a method to measure the moment of inertia quite accurately, and then we used the MOI to back-calculate the actual jet force. Furthermore, we were able to describe jet force as a mathematical function of manifold pressure, which we can measure in real time to account for regulator droop or other issues (such as multiple jets firing at once).

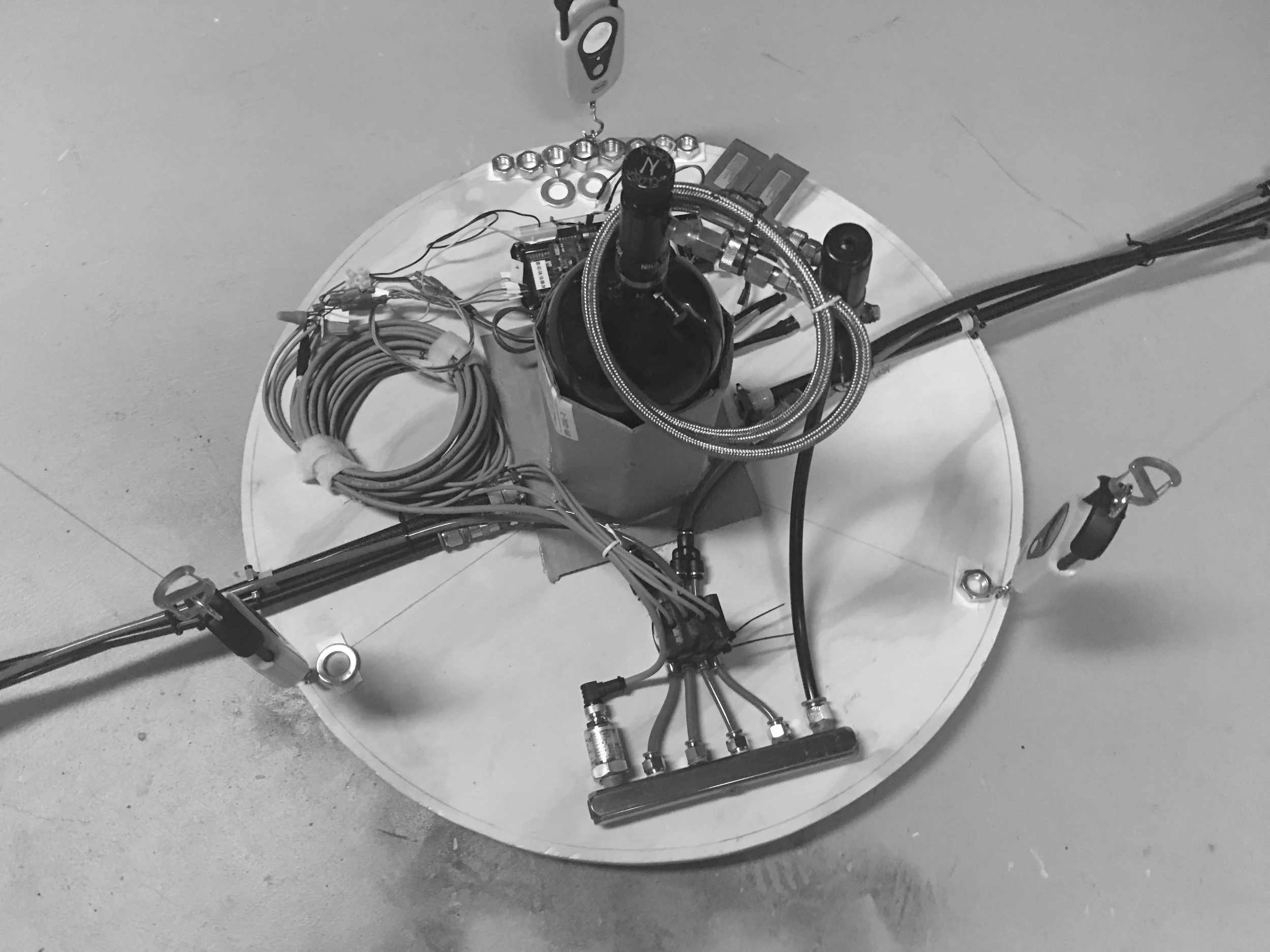

The HAPP apparatus at this point doesn't look much like the flight hardware we'll actually use in the future. Right now the apparatus is a jumble of plywood, cardboard, hot glue, tie straps, and a mess of wires and tubes. It only has arms and jets for a single axis (yaw). The only parts that are potential flight hardware are the Arduino controller and IMU, the carbon fiber jet arms and the 90 cubic inch carbon fiber compressed gas tank rated to 4600 PSI (normally used for paint ball!). However, it's all running on independent battery power and gas pressure - no connections to the outside world. Here's the test rig in all its sloppy glory: